Self-expanding stents manufactured by the BALTON Company are made of Nitinol wire (alloy of nickel and titanium).

They are designed for the use as intravascular prostheses helping to maintain the patency of vessels.

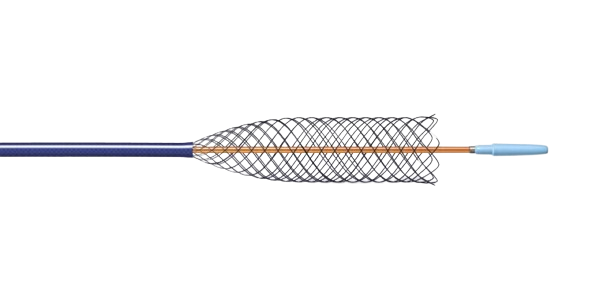

A stent is placed at the end of the delivery system. After being released from the delivery system, the stent opens up, taking the form of a cylinder.

The delivery system consists of a movable part and an immovable part. The stent is released by sliding the movable part off from the distal end of the immovable part of the delivery system. The markers indicate the nominal stent length.

The delivery system has two canals. The central canal is used to introduce the guide wire on which the delivery system is introduced. The other one, the external canal, constitutes the space separating the immovable part containing the stent, from the movable part. The unscrewing of the handwheel of the “Y” connector enables starting to slide off the movable part, thus releasing the stent.

As nitinol is faintly visible under scopy, platinum markers are placed on both stent ends to facilitate easier deployment during procedure. The delivery system is flexible and bendable, which enables implantation even in tortuous vessels. The rounded and flexible tip of the delivery system is atraumatic for the vessel wall.

During stent implantation it is possible to correct the location of partly expanded stent in the vessel. The delivery system allows stent reintroduction into the movable part. It is feasible when not more than half the stent length has expanded. Information about it is provided by the single mark on the steel tube that constitutes the immovable part during stent implantation. That single mark represents the limit which, when exceeded, shows that it is no longer possible to coil the stent again. The double mark represents the place in which the stent was completely released from the delivery system and expanded.

• Flexibility for proper adaptation to the vessel curvature.

• Flexion and compression resistant.

• Platinum markers on the stent endings.

• The “one-wire” stent technology (no welds and solders).

• Elevated ends of stent minimize risk of stent migration.

• The delivery system enabling stent repositioning after

its partial release.